Understanding material properties is very important for any industrial designer. Knowing how materials act in different conditions helps create new and useful designs. This blog post will teach you the key material properties every designer should know.

In industrial design, knowing about materials is crucial. It makes products work better and look and feel good. By learning about material properties, designers can make smart choices that lead to great designs.

Surface Properties

Surface properties of materials, often called the “skin,” are very important for how they work and look. These properties come from the natural surface, a finish that changes the material, or a process used to shape it.

For example:

- A smooth surface can be textured to improve grip or look better.

- Polishing or etching can change the surface to work better and feel nicer.

Understanding and changing these properties is key to making designs that work well and look good. This improves the user experience.

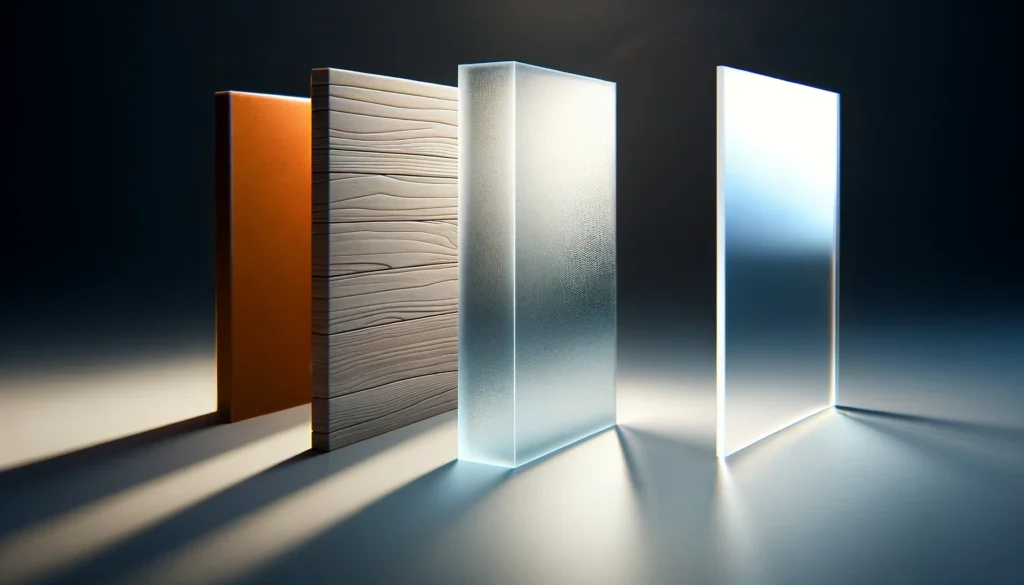

Opacity

Opacity shows how much light can go through a material. There are different levels of opacity:

- Opaque: No light passes through.

- Translucent: Some light passes through, but not clearly.

- Transparent: Light passes through clearly, like glass.

4o

Reflectivity

Reflectivity is the measure of how much light is reflected by a material. This property affects the visual appeal of the product and can be categorized as:

- Gloss: High reflectivity, shiny surface.

- Lustrous: Slightly shiny but less than gloss.

- Matte: No reflectivity, a dull surface.

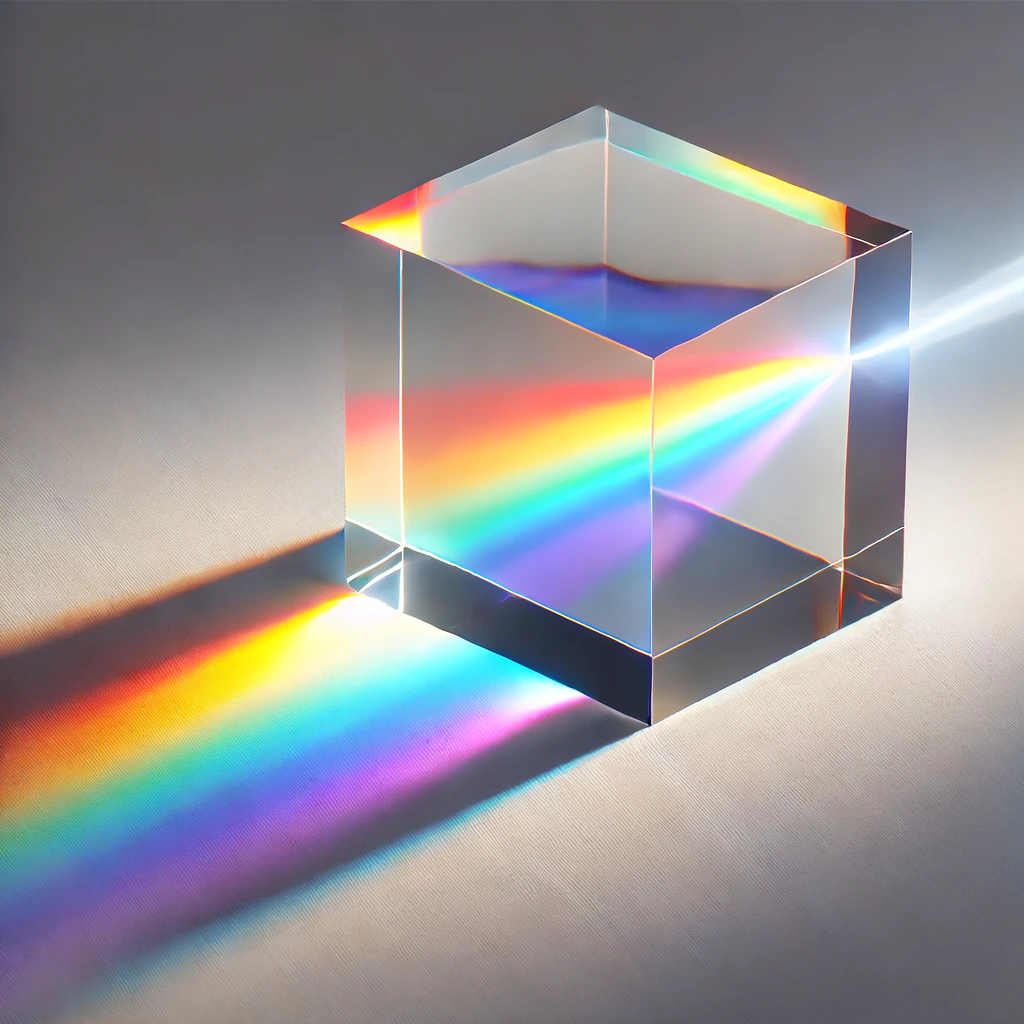

Refractiveness

Refractiveness shows how light bends when it goes through a material. This happens because light travels at different speeds in different materials. For example, when light moves from air into glass or water, it slows down and changes direction.

Refraction also causes dispersion. This means different colors of light bend at different angles, creating a rainbow effect, like in a prism. Knowing about refraction and dispersion helps designers control light, making things work better and look more attractive.

Colour

Color is an important material property influenced by several factors:

- Hue: The type of color, like red, blue, or green.

- Saturation: The intensity or purity of the color, showing how vivid or muted it is.

- Value: The lightness or darkness of the color, affecting its overall brightness.

These aspects of color are crucial in design. They impact how a product looks and how users perceive it. Understanding hue, saturation, and value helps designers create visually appealing and harmonious products, making them both functional and attractive in the market.

Luminosity

Luminosity is a material’s ability to emit light or glow. There are two main types of luminescent materials:

- Photoluminescent: Glows after absorbing light.

- Electroluminescent: Glows when an electric current passes through it.

These materials are important for many uses, like safety signs, emergency lighting, and cool product designs. For example, photoluminescent materials are used in glow-in-the-dark items, while electroluminescent materials are found in flexible displays and modern lighting.

Knowing about luminosity helps designers make products that are both eye-catching and useful, making them stand out in the market.

Hardness

Hardness is a material’s ability to resist scratches or dents. It’s important for knowing how durable a material is. Different scales measure hardness, such as the Shore scale for soft materials like rubber and the Brinell scale for hard materials like metals.

Understanding hardness helps designers choose materials that last longer and handle wear and tear. Hardness also affects how materials are used in different industries. For example:

- High hardness materials: Good for cutting tools.

- Lower hardness materials: Better for cushioning or protective gear.

Durability is a material’s ability to resist wear and tear, keeping its strength under tough conditions. This is important because it shows how well a material can handle erosion from friction and sliding against other surfaces. Durable materials are wear-resistant, making them last longer and be more reliable.

For example, materials used in high-traffic areas or mechanical parts need to be very durable to avoid frequent replacements. Understanding durability helps designers pick materials that last longer, reduce maintenance costs, and improve sustainability. Key factors that affect durability are the material’s makeup, surface treatments, and exposure to the environment.

Types of wear:

- Adhesive wear: Wear caused by surfaces sticking together.

- Abrasive wear: Wear caused by friction and scraping.

Coefficient of Friction

This property measures how easily a material slides against another. It ranges from:

- High grip: High friction, making it hard to slide.

- Low grip: Low friction, making it easy to slide.

Surface Roughness

Surface roughness shows the texture of a material’s surface. It ranges from:

- High roughness: Coarse and rugged texture.

- Low roughness: Smooth and polished texture.

Repellency

Repellency is the ability of a material to resist getting wet. There are two types:

- Hydrophilic: Attracts water.

- Hydrophobic: Repels water.

Bulk Properties

Bulk properties are those that are inherent throughout the material, not just on the surface. These include:

- Structural Properties

- Thermal Properties

- Energy Properties

Structural Properties

- Density: The mass per unit volume of a material.

- Porosity: The measure of void spaces in a material.

- Stress and Strain: The material’s response to forces.

- Elasticity: The ability of a material to return to its original shape after being deformed.

- Formability: Includes properties like ductility (ability to be stretched into a wire) and malleability (ability to be hammered into thin sheets).

- Young’s Modulus: A measure of a material’s stiffness.

- Strength: Includes compressive strength (resistance to being squished), tensile strength (resistance to being pulled apart), shear strength (resistance to sliding forces), and impact strength (resistance to sudden force).

- Fracture Toughness: The ability of a material to resist the spread of cracks.

Thermal Properties

- Thermal Conductivity: How well a material conducts heat.

- Coefficient of Expansion: How a material’s size changes with temperature.

- Flammability: How easily a material catches fire.

Energy Properties

- Magnetism: Whether a material is ferrous (contains iron) or non-ferrous, and its interactions with magnetic fields.

- Electrical Conductivity: How well a material conducts electricity.

- Acoustic Damping: The ability of a material to absorb sound.

Multidimensional Material Properties

These properties combine several attributes:

- Comfortability: How pleasant a material is to use or wear.

- Easy to Clean: How simple it is to keep the material clean.

- Durability: How well the material withstands wear and tear over time.

- Wide Operating Temperature: The range of temperatures within which the material can function effectively.

- Safety: How safe the material is to use, considering factors like toxicity and flammability.

By understanding and using these properties, designers can create products that are not only attractive but also functional and long-lasting. Knowing material properties is key to innovative design, helping to make superior products that meet user needs and expectations.